KIKOʻĪ

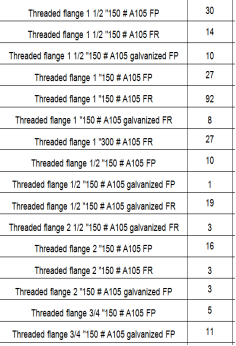

| Inoa Huahana | ʻO ke kaula kaula |

| Ka nui | 1/2"-24" |

| Kaomi | 150#-2500#,PN0.6-PN400,5K-40K |

| Kūlana Maʻamau | ANSI B16.5, EN1092-1, JIS B2220 etc. |

| ʻAno wili | NPT,BSP |

| Mea Hana | Kila kohu ʻole:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo a pēlā aku. |

| Ke kila kalapona:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24, A515 Gr60, A515 Gr 70 a pēlā aku. | |

| Ke kila kila ʻelua:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 a pēlā aku. | |

| Ke kila paipu:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 a pēlā aku. | |

| Mea hoʻohuihui nikala:ʻīnēl600, ʻīnēl625, ʻīnēl690, ʻīnēl800, ʻīnēl825, ʻīnēl800H,C22, C-276, Monel400, Alloy20 a pēlā aku. | |

| Mea hoʻohuihui Cr-Mo:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3, 15Crmo, a pēlā aku. | |

| Noi | ʻOihana petrochemical; ʻoihana mokulele a me ka aerospace; ʻoihana lāʻau lapaʻau; hoʻopau kinoea; mea kanu mana; kūkulu moku; mālama wai, a pēlā aku. |

| Nā Pōmaikaʻi | waihona mākaukau, manawa hoʻouna wikiwiki; loaʻa i nā nui āpau, i hoʻopilikino ʻia; kūlana kiʻekiʻe |

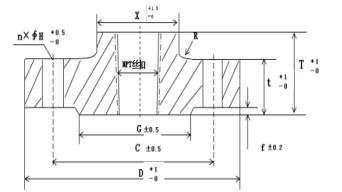

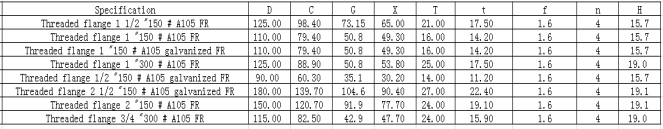

NĀ KŪLANA ANA

HŌʻIKEʻIKE KIKOʻĪ O NĀ HUAHANA

1. Maka

Hiki ke hoʻokiʻekiʻe ʻia ke alo (RF), ke alo piha (FF), ke apo hui (RTJ), Groove, Alohe, a i ʻole i hoʻopilikino ʻia.

2. Kaula

NPT a i ʻole BSP

3. Ua pau ka maikaʻi o CNC

Hoʻopau maka: Ua ana ʻia ka hoʻopau ma ka maka o ka flange ma ke ʻano he Arithmetical Average Roughness Height (AARH). Hoʻoholo ʻia ka hoʻopau e ke kūlana i hoʻohana ʻia. No ka laʻana, kuhikuhi ʻo ANSI B16.5 i nā hoʻopau maka i loko o kahi pae 125AARH-500AARH (3.2Ra a i 12.5Ra). Loaʻa nā hoʻopau ʻē aʻe ma ke noi ʻana, no ka laʻana 1.6 Ra max, 1.6/3.2 Ra, 3.2/6.3Ra a i ʻole 6.3/12.5Ra. ʻO ka pae 3.2/6.3Ra ka mea maʻamau.

KA HŌʻAILONA A ME KA HOʻOPILI ʻANA

• Hoʻohana kēlā me kēia papa i ka ʻili plastik e pale i ka ʻili

• No nā kila kila āpau, ua hoʻopili ʻia e ka hihia plywood. No ka nui nui aʻe, ua hoʻopili ʻia nā flange kalapona e ka pallet plywood. A i ʻole hiki ke hoʻopilikino ʻia.

• Hiki ke hana i ka māka hoʻouna ma ke noi

• Hiki ke kālai ʻia a paʻi ʻia paha nā māka ma nā huahana. Ua ʻae ʻia ʻo OEM.

NĀNĀ ʻANA

• Hoʻāʻo UT

• Hoʻāʻo PT

• Hoʻāʻo MT

• Hoʻāʻo ana

Ma mua o ka lawe ʻana, e hoʻonohonoho kā mākou hui QC i ka hoʻāʻo NDT a me ka nānā ʻana i ka ana.E ʻae pū iā TPI (nānā ʻaoʻao ʻekolu).

KAʻINA HANA

| 1. E koho i ka mea maka maoli | 2. E ʻoki i nā mea maka | 3. Hoʻomehana mua |

| 4. Ke hana ʻana | 5. Ka mālama wela | 6. Mīkini ʻŌpala |

| 7. ʻEli ʻana | 8. Hoʻopili maikaʻi ʻia | 9. Ke kaha ʻana |

| 10. Nānā ʻana | 11. Hoʻopili ʻana | 12. Hoʻouna ʻana |

HIHIA KŪKULU

No ka papahana Brazil kēia papahana. Pono kekahi mau mea i ka ʻaila anti-rust a pono kekahi i ka uhi galvanized.

Nā nīnau i nīnau pinepine ʻia

1. He aha ke kila kila 304?

ʻO ke kila kila 304 kahi kila kila austenitic i hoʻohana nui ʻia me ke kūpaʻa maikaʻi loa i ka pala, ka ikaika kiʻekiʻe a me ke ʻano maikaʻi. Hoʻohana nui ʻia ia ma nā ʻoihana like ʻole ma muli o kona versatility a me kona kūpaʻa.

2. He aha ke kila kila 304L?

ʻO ke kila kila 304L kahi ʻano kalapona haʻahaʻa o ke kila kila 304. Hāʻawi ia i ka hiki ke hoʻopili ʻia me ka mālama ʻana i ke kūpaʻa like ʻana i ka pala a me nā waiwai mechanical. Hoʻohana pinepine ʻia kēia papa i nā noi e pono ai ka hoʻopili ʻana.

3. He aha ke kila kila 316?

ʻO ke kila kila kila 316 kahi hui kila kila austenitic i loaʻa ka molybdenum e hoʻoikaika i kona kūpaʻa i ka pala i nā wahi kai a me ka chloride. Loaʻa iā ia ka ikaika maikaʻi loa a me ke kūpaʻa kolo kiʻekiʻe, e kūpono ana no nā ʻano hana koi like ʻole.

4. He aha ke kila kila 316L?

ʻO ke kila kila 316L kahi ʻano kalapona haʻahaʻa o ke kila kila 316. Ua hoʻomaikaʻi ʻia kona hiki ke kūʻai aku a me ke kūʻē ʻana i ka palaho intergranular. Hoʻohana pinepine ʻia kēia papa i nā noi e koi ana i ke kūʻē ʻana i ka palaho kiʻekiʻe a me ke ʻano maikaʻi loa.

5. He aha nā mea hoʻopili paipu wili i hoʻoheheʻe ʻia?

ʻO nā paipu wili i hoʻoheheʻe ʻia he mau paipu i hana ʻia ma ke kālai ʻana i ka metala wela a me ka hoʻohana ʻana i ka ikaika mechanical e hoʻololi iā ia i ke ʻano i makemake ʻia. Loaʻa i kēia mau mea hoʻopili nā kaula ma ka ʻili waho a hiki ke hoʻopili maʻalahi ʻia i ka paipu wili no kahi pilina palekana a ʻaʻohe leaka.

6. He aha ka flange?

ʻO ka flange kahi lihi waho a kūloko paha i hoʻohana ʻia e hoʻoikaika a hoʻohui paha i nā paipu, nā valves, a i ʻole nā ʻāpana ʻē aʻe i loko o kahi ʻōnaehana paipu. Hāʻawi lākou i kahi ala maʻalahi e hōʻuluʻulu, wehe a mālama i ka ʻōnaehana. Loaʻa i nā flanges kila kila maikaʻi loa ke kūpaʻa ʻana i ka pala a hiki ke kū i nā mahana kiʻekiʻe.

7. He aha nā kūlana ASTM no nā mea hoʻopili wili i hoʻoheheʻe ʻia a me nā flanges?

ʻO nā kūlana ASTM he mau kūlana i ʻike ʻia ma ka honua holoʻokoʻa i hoʻomohala ʻia e ka American Society for Testing and Materials. Hōʻoia kēia mau kūlana e hoʻokō nā mea hoʻopili wili a me nā flanges i hoʻopaʻa ʻia i nā koi kikoʻī no ka haku mele ʻana o nā mea, nā ana, nā waiwai mechanical a me nā kaʻina hana hoʻāʻo.

8. He aha nā pono o ka hoʻohana ʻana i nā paipu wili kila kila a me nā flanges?

Hāʻawi nā paipu wili kila kila a me nā flanges i nā pono like ʻole, me ke kūpaʻa maikaʻi loa i ka pala, ka ikaika kiʻekiʻe, ke kūpaʻa a me ka versatility. Hiki iā lākou ke kū i nā mahana koʻikoʻi, nā kaomi a me nā ʻano kaiapuni ʻino, e kūpono ai lākou no nā ʻano hana like ʻole.

9. Ma nā kahua hea e hoʻohana pinepine ʻia ai nā mea hoʻopili paipu wili kila kila a me nā flanges?

Hoʻohana nui ʻia kēia mau mea hoʻopili a me nā flanges i nā ʻoihana e like me ka ʻaila a me ke kinoea, ka petrochemical, kemika, ka hana mana, nā lāʻau lapaʻau, ka pulp a me ka pepa, ka hana ʻana i ka meaʻai a me ka mālama ʻana i ka wai. Hoʻohana pinepine ʻia lākou i nā ʻōnaehana paipu, nā pipelines, nā hale hoʻomaʻemaʻe a me nā noi ʻē aʻe kahi e pono ai nā pilina palekana a me ka hana hilinaʻi.

10. Pehea e koho ai i nā paipu wili kila kila kūpono a me nā flanges?

No ke koho ʻana i nā mea kūpono a me nā flanges, e noʻonoʻo i nā mea e like me nā koi noi, nā kūlana hana (mahana, kaomi, a me nā wahi ʻino), ka nui o ka paipu, a me ke kūlike me ka wai e lawe ʻia ana. Manaʻo ʻia e kūkākūkā me kahi mea hoʻolako akamai a ʻenekinia paha no ke alakaʻi ʻana i ke koho ʻana i nā mea kūpono a me nā flanges e kūpono i kāu mau pono kikoʻī.

He mau ʻāpana koʻikoʻi nā mea hoʻopili paipu i loko o ka ʻōnaehana paipu, hoʻohana ʻia no ka hoʻohui ʻana, ka hoʻohuli ʻana, ka hoʻohuli ʻana, ka hoʻololi ʻana i ka nui, ke sila ʻana a i ʻole ke kāohi ʻana i ke kahe o nā wai. Hoʻohana nui ʻia lākou ma nā kahua e like me ke kūkulu ʻana, ka ʻoihana, ka ikehu a me nā lawelawe kūlanakauhale.

Nā Hana Koʻikoʻi:Hiki iā ia ke hana i nā hana e like me ka hoʻohui ʻana i nā paipu, ka hoʻololi ʻana i ke kuhikuhi o ke kahe ʻana, ka māhele ʻana a me ka hoʻohui ʻana i nā kahe, ka hoʻoponopono ʻana i nā diameters paipu, ke sila ʻana i nā paipu, ka kaohi a me ka hoʻoponopono ʻana.

Ka laulā o ka noi:

- Ka hoʻolako wai a me ka hoʻokahe wai o ke kūkulu ʻana:Hoʻohana ʻia nā kuʻekuʻe PVC a me nā PPR tris no nā pūnaewele paipu wai.

- Nā paipu ʻoihana:Hoʻohana ʻia nā flanges kila kila a me nā kuʻekuʻe lima kila hao e lawe i nā mea kemika.

- Ka halihali ikehu:Hoʻohana ʻia nā mea hoʻopili paipu kila kiʻekiʻe i nā paipu aila a me ke kinoea.

- HVAC (Hoʻomehana, hoʻoulu ea, a me ke ea hoʻoluʻu):Hoʻohana ʻia nā mea hoʻopili paipu keleawe e hoʻohui i nā paipu refrigerant, a hoʻohana ʻia nā hui palupalu no ka hoʻēmi ʻana i ka haʻalulu.

- Ka hoʻoinu wai mahiʻai:Hoʻomaʻalahi nā mea hoʻohui wikiwiki i ka hōʻuluʻulu ʻana a me ka wehe ʻana o nā ʻōnaehana hoʻoinu wai sprinkler.

-

ʻO ke kumu hoʻopaʻa weld flange A105 kalapona kila SW RTJ 3/4 ...

-

ASTM A182 F51 F53 BL ANSI B16.5 Kila kila...

-

Kila kila 304 304L 316 316L ASTM i hoʻoheheʻe ʻia ...

-

ANSI B16.5 Forged kuhiliʻole kila Socket Weld F ...

-

ANSI DIN Forged Class150 kila kila pahee o ...

-

Flange i hoʻopilikino ʻia ANSI / ASME / JIS Standard Carbon ...